- Client Services: +8613673237939

- Email: sales@mambascreens.com

High Frequency Screen Polyurethane Fine Screen Used for Mining Sieve Machine

High Frequency Screen Polyurethane Fine Screen Used for Mining Sieve Machine

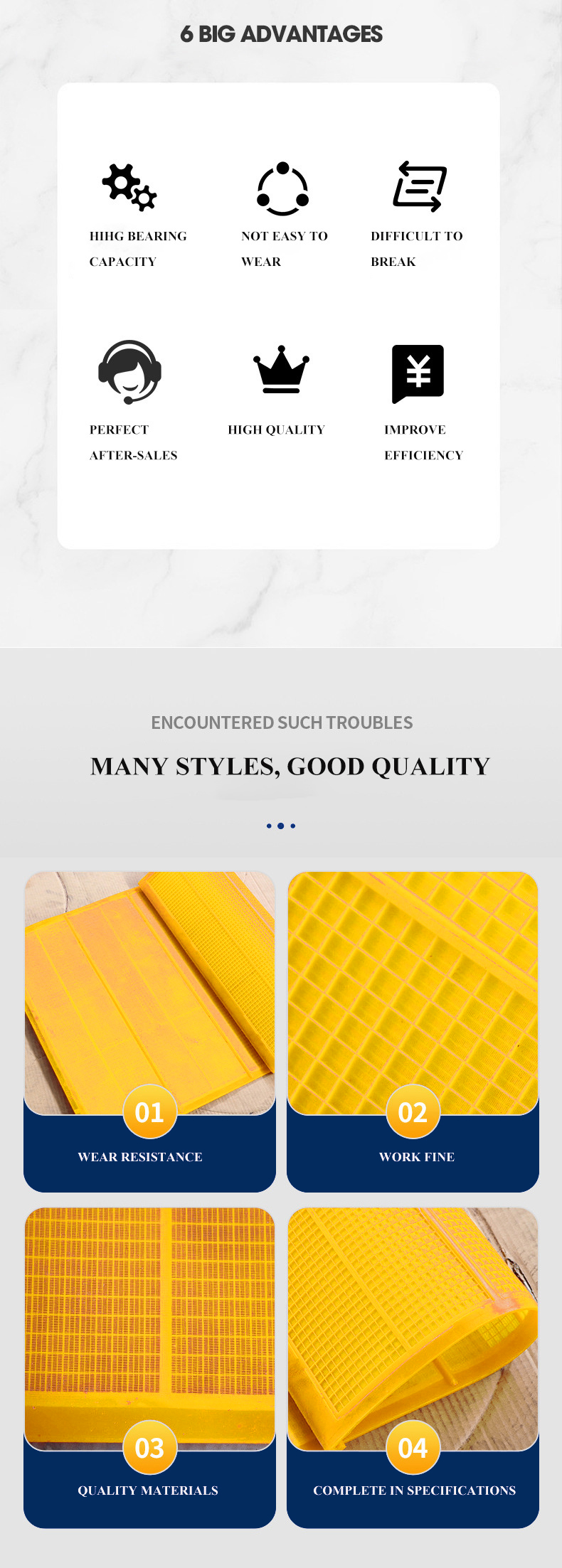

Polyurethane fine screen mesh is made of polyurethane sheet with high quality screen surface Polyurethane fine screen mesh is abrasion resistance and much longer service life than the woven vibrating screen mesh

Description

Polyurethane fine screen mesh is made of polyurethane sheet with high quality screen surface. Polyurethane fine screen mesh is abrasion resistance and much longer service life than the woven vibrating screen mesh. Moreover, the property of anti-blinding makes it feasible to screen materials which is considered difficult or impossible to screen previously. Polyurethane fine screen mesh has an extremely fine openings which is as fine as 0.05 mm, which is suitable for a wide variety of wet and dry applications.

| Item | Material | Thickness | Hole size |

| steel core polyurethane screen | steel wire inside and polyurethane outside | 2.5-5mm | 2-25mm |

| tensioned polyurethane screen | polyurethane and steel frame | 25-60mm | 5-50mm |

| modular polyurethane screen | polyurethane and embedded steel frame | 30-60mm | 2.5-130mm |

| polyurethane dewatering screen | steel frame and polyurethane surface | 30, 45, 50mm | 0.1-2.5mm(W), 4-16mm(L) |

In terms of mining screens, cast polyurethane (CPU) has the following advantages over thermoplastic polyurethane (TPU):

1. Higher strength and wear resistance: CPUs usually have higher strength, which makes them more resistant to wear and impact during the screening of hard materials such as ores, thus having a longer service life. For example, in the screening operation of large mines, CPU screens may be less likely to break or fracture under high-intensity working conditions than TPU screens, reducing the cost and downtime of frequent replacement due to screen damage. In the screening scenarios of some high-hardness ores, the advantages of CPU screens are more obvious.

2. Good chemical corrosion resistance: There may be various chemical substances in the mining environment. CPU has good chemical corrosion resistance, can resist the erosion of these chemical substances, and maintain the stability of the screen performance. In contrast, TPU may not perform as well as CPU in some highly corrosive environments. For example, in the screening of some ores containing acidic or alkaline substances, CPU screens can better adapt to this environment.

3. Excellent tear resistance: The ore may exert a large pulling force on the screen during the screening process. The excellent tear resistance of CPU can ensure that the screen is not easily torn during use, maintain the integrity of the screen structure, and ensure the normal screening work. TPU may be relatively weak in tear resistance.

4. Strong bonding with the metal frame: In the production of mining screens, it is usually necessary to combine with the metal frame. CPU and the metal frame can often form a strong bonding force, making the screen more firmly installed, and it is not easy to loosen or fall off during the vibration screening process, ensuring the efficiency and safety of screening. The bonding effect of TPU and the metal frame may be relatively poor.

5. Good dimensional stability: CPU can better maintain its dimensional stability during long-term use, and will not be significantly deformed due to changes in environmental factors such as temperature and humidity. This is very important for ensuring the screening accuracy of mining screens, which can keep the aperture of the screen uniform and improve the screening effect and product quality. In comparison, the dimensional stability of TPU may be slightly inferior.

Additional information

Get Free Quote