- Client Services: +8613673237939

- Email: sales@mambascreens.com

Polyurethane Tension Screen

Polyurethane Tension Screen

The polyurethane screen panels are a kind of screening media that made of polyurethane raw material Which is also called polyurethane sieve plates

Description

The polyurethane screen panels are a kind of screening media that made of polyurethane raw material. Which is also called polyurethane sieve plates.

Sieve hole type: bar seam, square, round, rectangular.

Application industries: coal washing plant, coking plants, mines, power plants, dredging companies, metallurgy, petroleum, petrochemical and other enterprises.

| Specification of Polyurethane Screen | |||

| Product Name | Material | Thickness | Hole size |

| Steel Core Polyurethane Screen | steel wire inside and polyurethane outside | 2.5-5mm | 2-25mm |

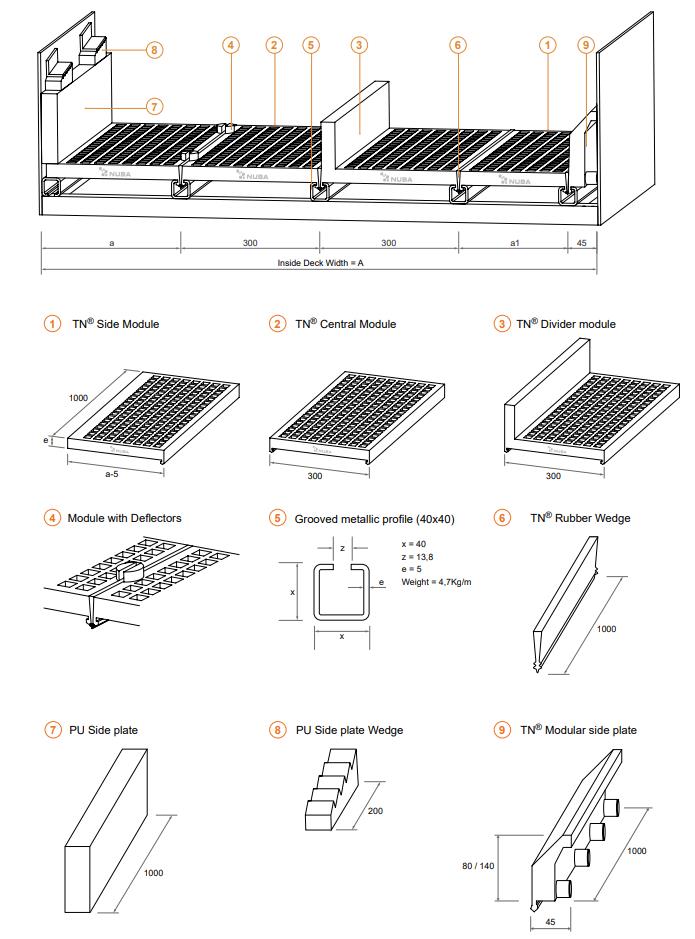

| Tensioned Polyurethane Screen | polyurethane and steel frame | 25-60mm | 5-50mm |

| Modular Polyurethane Screen Mesh | polyurethane and embedded steel frame | 30-60mm | 2.5-130mm |

| Polyurethane Dewatering Screen | steel frame and polyurethane surface | 30, 45, 50mm | 0.1-2.5mm(W), 4-16mm(L) |

Compared with metal screen and rubber screen, the advantages of polyurethane screen:

1. Polyurethane screen has high wear resistance, and its service life is 3-5 times that of metal screen and more than 5 times that of rubber screen. Can reduce maintenance volume and production loss.

2. Polyurethane screen is resistant to oil, water and corrosion. It can be applied to all kinds of mining conditions.

3. The friction coefficient of polyurethane screen and material is low, the screen is designed for conical hole, no adhesion, no blocking material, high screening efficiency.

4. Polyurethane screen has high elasticity, can produce secondary vibration, improve screening efficiency.

5. Polyurethane screen has good vibration absorption and low noise. Can reduce the noise interference of the working environment to the workers.

6. Polyurethane screen light weight, can reduce the screen machine screen machine load, prolong the life of the screen machine.

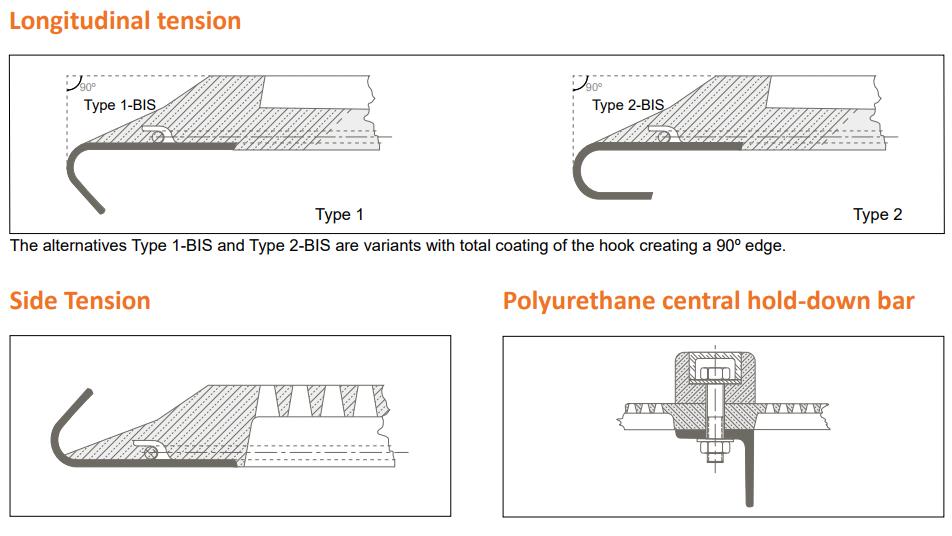

Type Of Tension

Additional information

Metallurgy(iron ore,limestone,fluorite,cooling blast furmace slag,coke,and other raw materials) colored,yellow,coal chemicals,building materials,water and electricity projects,abrasive waste disposal,quarries and other industries materials washing,screening,grading and other industries.A variety of standard format and size of the new structure of the sieve plate model,particularly strong impact,hardness,high wear-resistance require metns of the occasion.Sieving in the iron ore,coal grade,gold,building materials,as well as water and electricity,nuclear power engineering,such as screening the gravel with wear-resistant plate.

Get Free Quote