- Client Services: +8613673237939

- Email: sales@mambascreens.com

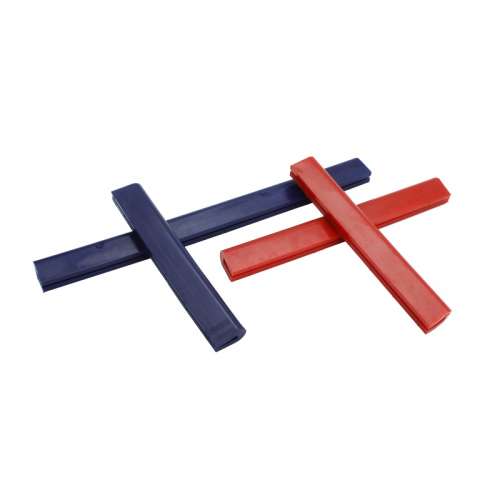

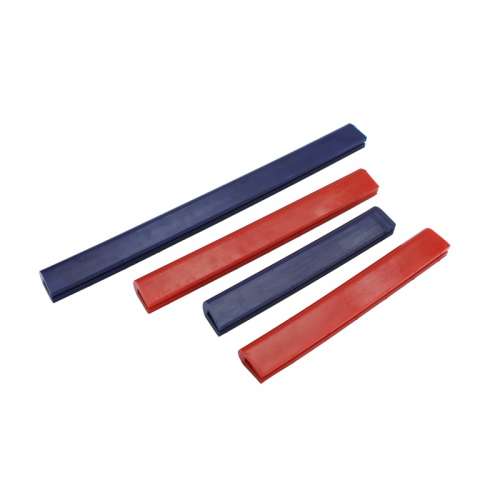

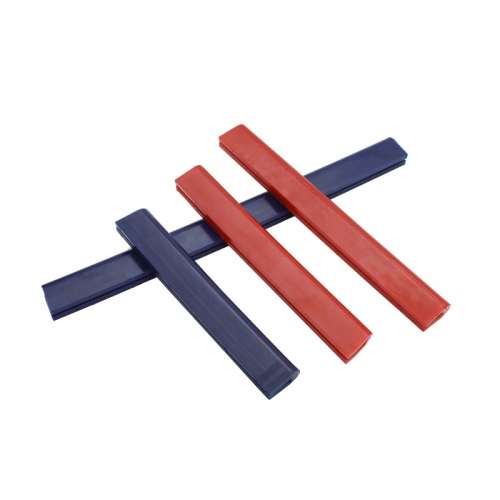

Polyurethane support strips

Polyurethane support strips

Polyurethane support strips are components used in vibrating screening equipment, typically employed to support the screen structure, enhancing its stability and durability

Description

Polyurethane support strips are components used in vibrating screening equipment, typically employed to support the screen structure, enhancing its stability and durability. Here's an overview of polyurethane support strips:

1. Material: Polyurethane support strips are primarily made from polyurethane (TPU) material. Polyurethane is a polymer material known for its excellent physical and chemical properties, making it particularly suitable for manufacturing industrial components that are wear-resistant and corrosion-resistant.

2. Structure: Polyurethane support strips typically have a strip-like structure, possessing some degree of flexibility and softness. This allows them to conform to the curved surfaces of vibrating screening equipment and provide uniform support for the screen while maintaining tension.

3. Characteristics: Polyurethane support strips exhibit good wear resistance, corrosion resistance, and high-temperature resistance, enabling them to operate stably for extended periods in harsh working environments. Additionally, they have some elasticity and flexibility, capable of absorbing vibration and impact, thus extending the service life of vibrating screening equipment and screens.

4. Application: Polyurethane support strips are widely used in various types of vibrating screening equipment, including rotary screens, linear vibrating screens, drum screens, etc. They are employed to support the screen structure, enhance its stability and durability, and improve screening efficiency and accuracy.

5. Advantages: Compared to traditional metal support strips, polyurethane support strips have the advantages of being lightweight, easy to install, resistant to rust, and less prone to wear. They can reduce maintenance costs and increase production efficiency.

In summary, polyurethane support strips are crucial components of vibrating screening equipment, possessing excellent material characteristics and application advantages. They find extensive use in screening and filtering equipment across various industrial sectors.

Characteristic

Polyurethane support strips possess various characteristics that make them essential components in vibrating screening equipment. Here are some of the key characteristics of polyurethane support strips:

1. Wear Resistance: Polyurethane support strips exhibit excellent wear resistance, capable of withstanding prolonged vibration and friction without significant wear, thus maintaining good operational condition.

2. Corrosion Resistance: These strips have good corrosion resistance, able to withstand the corrosion from chemicals and water, making them suitable for use in various working environments.

3. Elasticity: Polyurethane support strips have a certain degree of elasticity, enabling them to maintain stable shape during operation of vibrating screening equipment, thereby avoiding deformation or breakage and ensuring effective screening.

4. Flexibility: Due to their softness, polyurethane support strips can adapt to the curved surfaces of vibrating screening equipment, providing uniform support for the screen and maintaining its tension.

5. Temperature Resistance: These strips demonstrate good temperature resistance, allowing them to operate stably within a wide range of temperatures, suitable for screening operations in both high and low-temperature environments.

6. Lightweight: Compared to metal support strips, polyurethane support strips have a lighter weight, making vibrating screening equipment more portable and easier to install and maintain.

7. Shock Absorption: Polyurethane support strips can absorb vibration and impact, reducing the transmission of vibration in vibrating screening equipment, thereby decreasing equipment noise and vibration and improving the comfort of the working environment.

In summary, polyurethane support strips possess wear resistance, corrosion resistance, elasticity, flexibility, temperature resistance, lightweight construction, and shock absorption capabilities. These characteristics make them suitable for use in vibrating screening equipment across various industrial sectors, enhancing equipment stability and durability, and improving screening efficiency and product quality.

Additional information

Application

Polyurethane support strips are widely used in vibrating screening equipment to support and secure the screen structure, enhancing its stability and durability. Specific applications include but are not limited to the following:

1. Mining Industry: In mining and mineral extraction, polyurethane support strips are commonly used in vibrating screening equipment to sieve various ores, coal, and sands, separating materials of different particle sizes.

2. Construction Materials Industry: In the production of cement, sand, gravel, and mortar, polyurethane support strips are used in vibrating screening equipment to sieve and classify raw materials, controlling the particle size and quality of products.

3. Chemical Industry: In chemical production processes, polyurethane support strips are often used in vibrating screening equipment to sieve, classify, and filter chemical raw materials, extracting pure substances or removing impurities.

4. Food Processing: In the food industry, polyurethane support strips are employed in vibrating screening equipment to sieve and classify food raw materials such as flour, powdered sugar, and rice flour, ensuring product quality.

5. Environmental Engineering: In wastewater treatment and environmental projects, polyurethane support strips are commonly used in vibrating screening equipment to sieve and separate solid particles in wastewater, purifying it and protecting the environment.

6. Metallurgical Industry: In the metallurgical industry, polyurethane support strips are used in vibrating screening equipment to sieve and filter metal ores, as well as in the production of metal powders.

In summary, polyurethane support strips play a crucial role in vibrating screening equipment across various industries, improving screening efficiency, controlling product quality, and enhancing production benefits.

Get Free Quote