- Client Services: +8613673237939

- Email: sales@mambascreens.com

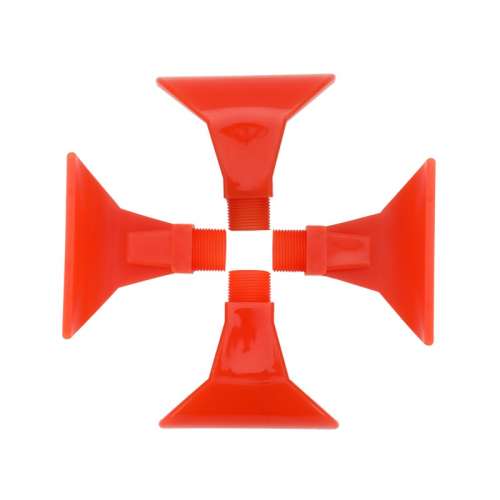

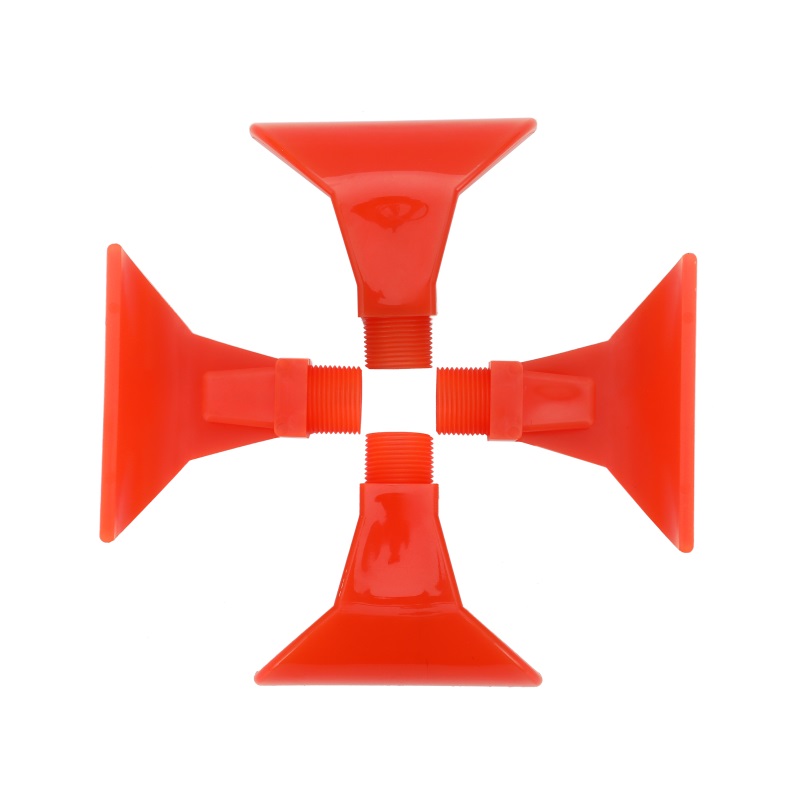

Polyurethane Spray Nozzle

Polyurethane Spray Nozzle

An atomizing spray nozzle is a device used to produce atomized water mist, typically employed in air purification, dust suppression, cooling, and humidification applications It works by spraying water or other liquids through specially designed nozzles, breaking them into tiny water droplets or mist particles, thereby generating fine water mist

Description

An atomizing spray nozzle is a device used to produce atomized water mist, typically employed in air purification, dust suppression, cooling, and humidification applications. It works by spraying water or other liquids through specially designed nozzles, breaking them into tiny water droplets or mist particles, thereby generating fine water mist. These water mist particles can float in the air, serving purposes such as humidification, dust suppression, and air cleaning.

The working principle of an atomizing spray nozzle usually involves utilizing the internal structure of the nozzle design to pass liquid through high-speed flow or special nozzle designs to break the liquid into tiny particles. These tiny particles are then carried by the force of wind or airflow, forming a mist and dispersing into the air.

The main components of an atomizing spray nozzle include the nozzle body, liquid inlet, atomizing orifice, and nozzle base, among others. Different atomizing spray nozzles have different structures and working principles, and one can choose the appropriate model and specifications based on specific application requirements.

Features:

Designed for wet screening and dust control applications

Standard 3/4" NPT Couplings

These rugged and reliable polyurethane spray nozzles will stay firmly fixed to your spray bar.

The integral, molded-in spray orifice delivers dependable, constant spray volume and spray width to the material bed

Fans cannot be separated from the nozzle. Your screens will never be ruined by direct spray because of a displaced fan

The characteristics of an atomizing spray nozzle are as follows:

Fine Atomization Effect: Atomizing spray nozzles can spray water or liquid into tiny water mist particles, typically ranging in diameter from tens of micrometers to several hundred micrometers, or even smaller. This fine atomization effect allows the water mist to be evenly distributed in the air and more easily dispersed by airflow.

Water and Energy Saving: Compared to traditional nozzles or sprayers, atomizing spray nozzles can effectively utilize water resources, achieving water and energy savings. By refining the water mist, the amount of water used can be reduced while covering the same area, thereby reducing water waste.

Uniform Distribution: Atomizing spray nozzles can evenly distribute water mist in the air, forming a uniform mist. This uniform distribution characteristic allows the water mist to cover a wider range, thereby achieving better humidification, dust suppression, and other effects.

Adjustability: Some atomizing spray nozzles have adjustable parameters such as spray angle and spray volume, which can be adjusted and controlled according to specific requirements. This adjustability makes atomizing spray nozzles more flexible, suitable for different application scenarios and needs.

Corrosion Resistance: Atomizing spray nozzles are typically made of corrosion-resistant materials, able to resist corrosion from corrosive media and maintain long-term stable performance.

Easy Installation: Atomizing spray nozzles are usually easy to install and can be directly connected to water supply pipes or spray systems. They can be operated by adjusting water flow pressure and nozzle position.

Diverse Applications: Atomizing spray nozzles are widely used in air purification, cooling and dust suppression, humidification, spraying chemical agents, and other fields. They are suitable for industrial production, agricultural irrigation, urban environmental purification, greenhouse cultivation, and other occasions.

In summary, atomizing spray nozzles have the characteristics of fine atomization effect, water and energy saving, uniform distribution, adjustability, corrosion resistance, easy installation, and diverse applications, making them a common and effective spraying equipment.

Additional information

Get Free Quote